How to connect the electric motor 220?

Watch the video

If you have a single-phase asynchronouselectric motor from the old washing machine, it can easily be converted to manual starting from the 220V network. This will allow using it for a homemade grindstone or lawnmower. Before starting to improve the motor circuit and to assemble a new device, it is necessary to prepare tools such as a soldering iron, a knife (for wiring), a capacitor of the required power and heat-shrink tubes. A multimeter may also be required to wind the windings.

How to connect the electric motor to the network?

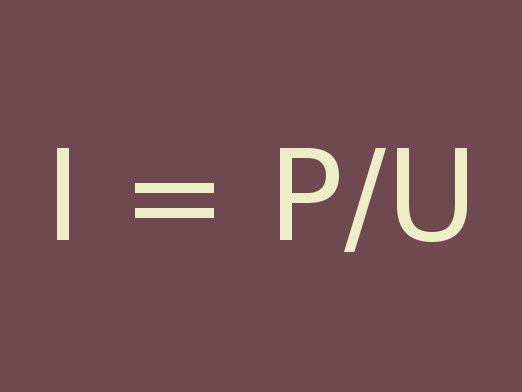

The process of connecting single-phase asynchronousengine is simple enough for those who are at least a little knowledgeable in technology. Due to the fact that this type of engines is equipped with a separate starting winding, which is fed through the capacitor, a smooth start and a quick set of maximum revolutions occur. In a similar way, you can connect the 380V motor to a 220V network.

Connecting an asynchronous motor to 220 volts:

- Connect the main winding wires directly to the electrical outlet;

- Connect one of the wires of the starting winding directly to the outlet to the mains;

- The second wire of the starting winding is connected to the capacitor (its power is selected from the calculation of 6 μF per 1,4A);

- Connect the capacitor to the start button, which will allow starting starting winding only at the time of engine start;

- Switch the starting button to the second wire leading to the outlet on the mains.

If it is necessary to change directionrotation of the motor, it is only necessary to change the polarity at the input of the mains. Connect the engine to 220V in other ways, but they are more difficult to implement.