How are cars assembled?

Watch the video

Not very many are given the opportunity to see how the process of assembling cars in the factory is going on. In fact, it's quite interesting.

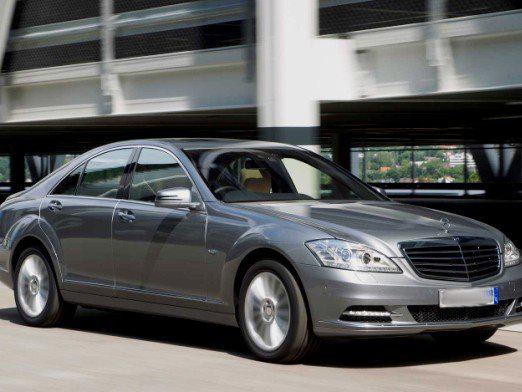

In Russia, there are a lot of auto plants thatare engaged. Moreover, in Russia, both UAZ, KamAZ, ZIL, GAZ, and various foreign cars of General Motors, Iveco, Toyota, Volvo, Mercedes-Benz, Ford, Volkswagen and many others are assembled. About the Russian assembly, you can read more in the article What cars are collected in Russia.

Let's look at how cars are assembled, what procedures and stages each car goes through in order to be absolutely ready for sale.

Welding shop

- Of course, car production begins withbodywork. It is in this shop that all the details are supplied, both from Russia and from other countries, depending on the brand of the car with which the workshop staff works. The logistics department is responsible for the delivery and receipt of the parts, their purchase and others.

- Welding is done manually, but, to avoiddefects, the procedure is completely standardized. Moreover, in order to avoid monotony of work, which increases the risk of a defect, employees rotate through all stations of the workshop.

- Each body has about 2.8 thousand weld points, so the general procedure consists of seven stages.

- First, the engine compartment is welded, the front and rear floors, side walls and the rest of the floor. After that with the help of a semi-automatic the other side walls and a roof join.

- The last stages of the assembly - the wings, doors, hood, trunk and, accordingly, polishing the finished body.

Painting shop

This process is considered the most difficult in the whole procedure. Employees are dressed in a special lint-free form, the requirements for cleanliness are very high.

- First, cleaning, degreasing the body and other work.

- Further special water repellent and sound-absorbing materials are applied.

- A special primer is applied, which is fixedin an oven at high temperature. This shop is maximally automated, and the application of the paint itself is done by robots. Next, the car passes the drying procedure.

Assembly shop

Operators of this workshop, first of all, apply wax in the wax chamber to provide additional resistance to corrosion.

All heavy elements are also installed using automated equipment. At this stage the machine is equipped with all the elements necessary for its existence.

In the same workshop, the car's quality control is carried out: testing for external and internal defects, dynamic testing, checking the sealing of the passenger compartment.

Further the car is deduced in real conditions of operation and also passes a line of tests then the conclusion on suitability of the car is done. Approximately here and collect the car.

Assemble the car with your own hands will help you article How to assemble a car.